Overview of Automotive Sensors

Overview of Automotive Sensors - SENSORS are essential components of automotive electronic control systems. Sensors are defined as [1] “devices that transform (or transduce) physical quantities such as pressure or acceleration (called measurands) into output signals (usually electrical) that serve as inputs for control systems.”

It wasn’t that long ago that the primary automotive sensors were discrete devices used to measure oil pressure, fuel level, coolant temperature, etc. Starting in the late 1970s, microprocessor-based automotive engine control modules were phased in to satisfy federal emissions regulations.

These systems required new sensors such as MAP (manifold absolute pressure), air temperature, and exhaust-gas stoichiometric air-fuel-ratio operating point sensors. The need for sensors is evolving and is progressively growing.

For example, in engine control applications, the number of sensors used will increase from approximately ten in 1995, to more than thirty in 2010, as predicted in [2]. Automotive engineers are challenged by a multitude of stringent requirements.

For example, automotive sensors typically must have combined/total error less than 3 % over their entire range of operating temperature and measurand change, including all measurement errors due to nonlinearity, hysteresis, temperature sensitivity and repeatability.

Moreover, even though hundreds of thousands of the sensors may be manufactured, calibrations of each sensor must be interchangeable within 1 percent.

Automotive environmental operating requirements are also very severe, with temperatures of 40 to 125 C (engine compartment), vibration sweeps up to 10 g for 30 h, drops onto concrete floor (to simulate assembly mishaps), electromagnetic interference and compatibility, and so on.

When purchased in high volume for automotive use, cost is also always a major concern. Mature sensors (e.g., pressure types) are currently sold in large-quantities (greater than one million units annually) at a low cost of less than $3 (US) per sensor (exact cost is dependent on application constraints and sales volume), whereas more complex sensors (e.g., exhaust gas oxygen, true mass intake air flow and angular rate) are generally several times more costly.

Automotive sensors must, therefore, satisfy a difficult balance between accuracy, robustness, manufacturability, interchangeability, and low cost. Important automotive sensor technology developments are micromachining and microelectromechanical systems (MEMS).

MEMS manufacturing of automotive sensors began in 1981 with pressure sensors for engine control, continued in the early 1990s with accelerometers to detect crash events for air bag safety systems and in recent years has further developed with angular-rate inertial sensors for vehicle-stability 1 chassis systems.

What makes MEMS important is that it utilizes the economy of batch processing, together with miniaturization and integration of on-chip electronic intelligence. Simply stated, MEMS makes high-performance sensors available for automotive applications, at the same cost as the traditional types of limited-function sensors they replace.

In other words, to provide performance equal to today’s MEMS sensors, but without the benefits of MEMS technology, sensors would have to be several times more expensive if they were still made by traditional electromechanical/discrete electronics approaches.

OBJECTIVE

MEMS-based automotive sensor technology was recently reviewed by Eddy and Sparks [5]. Frank’s 1997 publication [6] emphasized electronic circuits and sensor manufacture. Two classic references on automotive sensors include: Wolber’s 1978 publication [7] and Heintz and Zabler’s 1982 publication [8].

The objective of the present paper is to provide an up-to-date overview of current-production and emerging state-of the-art, automotive sensor technologies.

SENSOR CLASSIFICATION

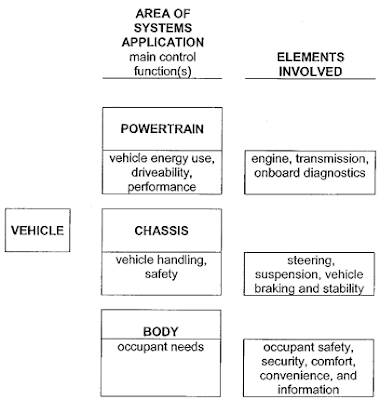

As shown in Fig. 1, the three major areas of systems application for automotive sensors are powertrain, chassis, and body. In the present systems-classification scheme, anything that isn’t powertrain or chassis is included as a body systems application.

Fig. 1 also identifies the main control functions of each area of application and the elements of the vehicle that are typically involved. The automotive industry has increasingly utilized sensors in recent years.

The penetration of electronic systems and the associated need for sensors is summarized in Table I. Powertrain applications for sensors, shown in Table I, can be thought of as the “1st Wave” of increased use of automotive sensors because they led the first widespread introduction of electronic sensors.

Chassis applications for sensors are considered to be the “2nd Wave” of increased use of sensors, and body applications are called the “3rd Wave.” Automotive control functions and associated systems for powertrain, chassis and body areas of application are shown, respectively, in Figs. 2–4.

These diagrams help to classify the various applications for automotive sensors. Tables II–IV provide additional detail on the types of sensors used in automotive applications.

In these Tables, if sensors are universally used in automotive applications, they are denoted as having a “major” production status; if the sensors are used in just a few automotive models, but not universally used, they’re denoted as having “limited” production status, and some promising sensors which are getting close to production are denoted as having “R&D” status.

TableII shows that certain types of sensors predominate in powertrain application, namely rotational motion sensors,4 pressure, and temperature. In North America, these three types of sensors rank, respectively, number one, two, and four in unit sales volume [9].

To illustrate the predominance of these sensors, there are a total of 40 different sensors listed in Table II, of which eight are pressure sensors, four are temperature sensors, and four are rotational motion sensors.

Newtypesof recently introduced powertrain sensors, listed in Table II, include the cylinder pressure, pedal/accelerator rotary position, and oil quality sensors. Table III shows that certain types of sensors also predominate in chassis applications, namely rotational motion and pressure (these two types were also predominate in powertrain).

But, instead of temperature, inertial acceleration and angular-rate sensors round out the four types of predominant sensors. To illustrate this predominance, there are a total of 27 different sensors listed, of which four are pressure sensors, three are rotational motion sensors, five are acceleration sensors and three are angular rate sensors.

Posting Komentar untuk "Overview of Automotive Sensors"