WHAT IS MANUFACTURING?

WHAT IS MANUFACTURING? - The word manufacture is derived from two Latin words, manus (hand) and factus (make); the combination means made by hand. The English word manufacture is several centuries old, and ‘‘made by hand’’ accurately described the manual methods used when the word was first coined.1 Most modern manufacturing is accomplished by automated and computer-controlled machinery.

Manufacturing Defined

As a field of study in the modern context, manufacturing can be defined two ways, one technologic and the other economic.

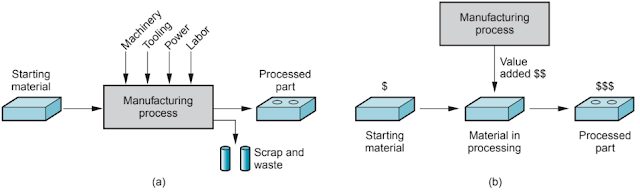

Technologically, manufacturing is the application of physical and chemical processes to alter the geometry, properties, and/or appearance of a given starting material to make parts or products; manufacturing also includes assembly of multiple parts to make products.

The processes to accomplish manufacturing involve a combination of machinery, tools, power, and labor, as depicted in Figure.

Manufacturing is almost always carried out as a sequence of operations. Each operation brings the material closer to the desired final state. Economically, manufacturing is the transformation of materials into items of greater value by means of one or more processing and/or assembly operations, as depicted in Figure.

The key point is that manufacturing adds value to the material by changing its shape or properties, or by combining it with other materials that have been similarly altered. Thematerial has beenmade more valuable through the manufacturing operations performed on it.

When iron ore is converted into steel, value is added. When sand is transformed into glass, value is added.When petroleum is refined into plastic, value is added. And when plastic is molded into the complex geometry of a patio chair, it is made even more valuable.

The words manufacturing and production are often used interchangeably. The author’s view is that production has a broader meaning than manufacturing.

To illustrate, one might speak of‘‘crude oil production,’’ but the phrase ‘‘crude oil manufacturing’’seems out of place. Yet when used in the context of products such as metal parts or automobiles, either word seems okay.

Manufacturing Industries and Products

Manufacturing is an important commercial activity performed by companies that sell products to customers. The type of manufacturing done by a company depends on the kind of product it makes. Let us explore this relationship by examining the types of industries in manufacturing and identifying the products they make.

1. Manufacturing Industries

Industry consists of enterprises and organizations that produce or supply goods and services. Industries can be classified as primary, secondary, or tertiary. Primary industries cultivate and exploit natural resources, such as agriculture and mining.

Secondary industries take the outputs of the primary industries and convert them into consumer and capital goods. Manufacturing is the principal activity in this category, but construction and power utilities are also included.

Tertiary industries constitute the service sector of the economy. A list of specificindustries in these categories is presented in Table. This book is concerned with the secondary industries in Table 1.2, which include the companies engaged in manufacturing.

However, the International Standard Industrial Classification (ISIC) used to compile Table 1.2 includes several industries whose production technologies are not covered in this text; for example, beverages, chemicals, and food processing.

In this book, manufacturing means production of hardware, which ranges from nuts and bolts to digital computers and military weapons. Plastic and ceramic products are included, but apparel, paper, pharmaceuticals, power utilities, publishing, and wood products are excluded.

2. Manufactured Products

Final products made by the manufacturing industries can be divided into two major classes: consumer goods and capital goods. Consumer goods are products purchased directly by consumers, such as cars, personal computers, TVs, tires, and tennis rackets.

Capital goods are those purchased by companies to produce goods and/or provide services. Examples of capital goods include aircraft, computers, communication equipment, medical apparatus, trucks and buses, railroad locomotives, machine tools, and construction equipment.

Most of these capital goods are purchased by the service industries. It was noted in the Introduction that manufacturing accounts for about 15% of GDP and services about 75% of GDP in the United States. Yet the manufactured capital goods purchased by the service sector are the enablers of that sector. Without the capital goods, the service industries could not function.

In addition to final products, other manufactured items include the materials, components, and supplies used by the companies that make the final products. Examples of these items include sheet steel, bar stock, metal stampings, machined parts, plastic moldings and extrusions, cutting tools, dies, molds, and lubricants.

Thus, the manufacturing industries consist of a complex infrastructure with various categories and layers of intermediate suppliers with whom the final consumer never deals. This book is generally concerned with discrete items—individual parts and assembled products, rather than items produced by continuous processes.

A metal stamping is a discrete item, but the sheet-metal coil from which it is made is continuous (almost). Many discrete parts start out as continuous or semicontinuous products, such as extrusions and electrical wire.

Long sections made in almost continuous lengths are cut to the desired size. An oil refinery is a better example of a continuous process.

Production Quantity and Product Variety The quantity of products made by a factory has an important influence on the way its people, facilities, and procedures are organized. Annual production quantities can be classified into three ranges:

- low production, quantities in the range 1 to 100 units per year;

- medium production, from 100 to 10,000 units annually; and

- high production, 10,000 to millions of units.

on the kinds of products, these boundaries may shift by an order of magnitude or so. Production quantity refers to the number of units produced annually of a particular product type.

Some plants produce a variety of different product types, each type being made in low or medium quantities. Other plants specialize in high production of only one product type. It is instructive to identify product variety as a parameter distinct from production quantity.

Product variety refers to different product designs or types that are produced in the plant. Different products have different shapes and sizes; they perform different functions; they are intended for different markets; some have more components than others; and so forth.

The number of different product types made each year can be counted. When the number of product types made in the factory is high, this indicates high product variety. There is an inverse correlation between product variety and production quantity in terms of factory operations.

If a factory’s product variety is high, then its production quantity is likely to be low; but if production quantity is high, then product variety will be low, as depictedin Figure 1.2.Manufacturing plants tend to specializein a combination of production quantity and product variety that lies somewhere inside the diagonal band in Figure 1.2.

Although product variety has been identified as a quantitative parameter (the number of different product types made by the plant or company), this parameter is much less exact than production quantity, because details on how much the designs differ are not captured simply by the number of different designs.

Differences between an automobile and an air conditioner are far greater than between an air conditioner and a heat pump. Within each product type, there are differences among specific models.

The extent of the product differences may be small or great, as illustrated in the automotive industry.

Each of the U.S. automotive companies produces cars with two or three different nameplates in the same assembly plant, although the body styles and other design features are virtually the same. In different plants, the company builds heavy trucks.

The terms ‘‘soft’’ and ‘‘hard’’ might be used to describe these differences in product variety. Soft product variety occurs when there are only small differences among products, such as the differences among car models made on the same production line. In an assembled product, soft variety is characterized by a high proportion of common parts among the models.

Hard product variety occurs when the products differ substantially, and there are few common parts, if any. The difference between a car and a truck exemplifies hard variety.

Manufacturing Capability

A manufacturing plant consists of a set of processes and systems (and people, of course) designed to transform a certain limited range of materials into products of increased value. These three building blocks—materials, processes, and systems—constitute the subject of modern manufacturing.

There is a strong interdependence among these factors. A company engaged in manufacturing cannot do everything. It must do only certain things, and it must do those things well. Manufacturing capability refers to the technical and physical limitations of a manufacturing firm and each of its plants. Several

dimensions of this capability can be identified:

- technological processing capability,

- physical size and weight of product, and

- production capacity.

Technological Processing Capability

The technological processing capability of a plant (or company) is its available set of manufacturing processes. Certain plants perform machining operations, others roll steel billets into sheet stock, and others build automobiles.

A machine shop cannot roll steel, and a rolling mill cannot build cars. The underlying feature that distinguishes these plants is the processes they can perform. Technological processing capability is closely related to material type.

Certain manufacturing processes are suited to certain materials, whereas other processes are suited to other materials. By specializing in a certain process or group of processes, the plant is simultaneously

specializing in certain material types.

Technological processing capability includes not only the physical processes, but also the expertise possessed by plant personnel in these processing technologies. Companies must concentrate on the design and manufacture of products that are compatible with their technological processing capability.

Physical Product Limitations

A second aspect of manufacturing capability is imposed by the physical product. A plant with a given set of processes is limited in terms of the size and weight of the products that can be accommodated. Large, heavy products are difficult to move.

To move these products about, the plant must be equipped with cranes of the required load capacity. Smaller parts and products made in large quantities can be moved by conveyor or other means. The limitation on product size and weight extends to the physical capacity of the manufacturing equipment as well.

Production machines come in different sizes. Larger machines must be used to process larger parts. The production and material handling equipment must be planned for products that lie within a certain size and weight range.

Production Capacity

A third limitation on a plant’s manufacturing capability is the production quantity that can be produced in a given time period (e.g., month or year). This quantity limitation is commonly called plant capacity, or production capacity, defined as the maximum rate of production that a plant can achieve under assumed operating conditions.

The operating conditions refer to number of shifts per week, hours per shift, direct labor manning levels in the plant, and so on.

These factors represent inputs to the manufacturing plant. Given these inputs, how much output can the factory produce? Plant capacity is usually measured in terms of output units, such as annual tons of

steel produced by a steel mill, or number of cars produced by a final assembly plant.

In these cases, the outputs are homogeneous. In cases in which the output units are not homogeneous, other factors may be more appropriate measures, such as available labor hours of productive capacity in a machine shop that produces a variety of parts.

Materials, processes, and systems are the basic building blocks of manufacturing and the three broad subject areas of this book. This introductory chapter provides an overview of these three subjects before embarking on detailed coverage in the remaining chapters.

Posting Komentar untuk "WHAT IS MANUFACTURING?"